The Helicopter Engine (Turboshaft)

(Reviewed on 12th March 2021)

Helicopter Engines

Helicopter Engines

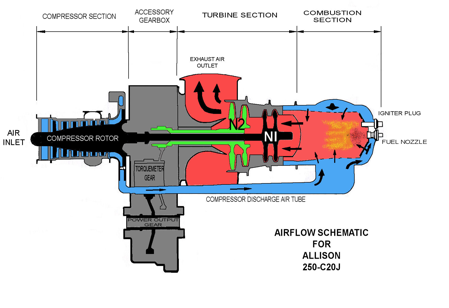

One of the most common helicopter engines used today is the turboshaft engine. A turboshaft engine is effectively a jet engine and normally runs on a kerosene based fuel. There are many variants of turboshaft engines but they all follow basic concepts and principles. To keep things simple, I will be referring to the engine used by the Bell 206 JetRanger. The Rolls Royce Allison 250/c20J.

The working cycle of the turbine engine is similar to that of the piston engine. There is induction, compression, combustion and exhaust. The major difference is that unlike the piston engine, the turbine engines cycles are continuous. Unlike airplane jet engines where the exhaust gases provide the thrust, the exhaust gases for the helicopter turbo shaft engine are intercepted by a turbine that transfers the energy from these gases to a gearbox that provides power for the helicopter.

It is vital that you learn not to over-torque or over-temp the engine as this can have disastrous consequences for someone flying it, weeks or even months later. Misusing the engine will not necessarily cause a problem right away.

Starting the helicopter engine causes more stress to the components than just about any other operation due to thermal shock and wear. For this reason, the start cycles are counted and recorded in the technical log after each flight. As helicopters tend to fly for short periods compared to airplanes, it is possible that the engine could reach its start count limit before it reaches its useful life hour limit. Start-ups are expensive and so it is better to leave the engine running for ten minutes while waiting for a passenger rather than shutting the engine down and then starting up again.

The engine relies totally on the battery or Auxiliary Power Unit (APU) for startup. The engine has to be turning fast enough to keep enough cold air flowing through the turbine otherwise it will become very hot and damage the internal components. A weak battery could run out of power before the combustion process becomes self sustaining and this would be disastrous.

A “Hung Start” can happen if the engine fails to accelerate and the RPM stays constantly low. This uses up your battery power and if the battery runs out of power then the engine slows down, less and less cold air is drawn through the engine and subsequently the temperature in the combustion chamber becomes really hot within a few seconds causing a lot of damage.

A “Wet Start” is the equivalent of a flooded engine and the igniter has failed to light the fuel. Wait for at least 5 minutes and then vent the engine. Because the battery has already been partially drained by the failed start and the venting, it is probably a good idea to get an external start using an APU to make sure you do not run out of power on your next start attempt.

If you follow the check list exactly then you should have no problem starting the helicopter engine every time. The most common reason I have seen for hot starts is low time pilots starting the engine with the throttle already partially (or fully) open.

Therefore it is vital for you to double check that the throttle is fully closed before pressing the starter button.

Turbine engines take time to “Spool up” or “Spool down” when you make power changes. For this reason you should operate the collective or throttle very smoothly to prevent engine “surging”. Surging can happen when the airflow over the compressor blades becomes disturbed causing them to stall. This leads to loud banging noises (similar to a shotgun going off) and a very noticeable vibration from the engine. Shut down immediately if this happens during startup.

The Air Inlet

The air inlet is designed to stabilize the air before it enters the compressor. A particle separator may be fitted at this point to remove any foreign matter such as dust or sand which could cause erosion of the compressor blades.

The Compressor

The compressor is made up of a series of blades and an impellor (or centrifugal) compressor. It is designed to take large quantities of air and compress it before directing it to the combustion section.

The engine in the JetRanger has a six stage axial flow compressor and a single impellor compressor.

In the axial compressor, each stage is separated by stator vanes to make sure the air hits the following blades at the correct angle. As the air flows past these blades it becomes compressed more and more. The pressure rises and its velocity decreases.

The centrifugal compressor diverts the air outwards into channels that lead to the combustion section while compressing the air further.

During startup there is a bleed valve that opens and allows some of the air to escape from the compressor. This makes it easier to get the engine up to speed and takes less power from the battery. When the engine reaches a sustainable speed the valve closes automatically.

Because of the high temperatures of the compressed air in the compressor section (up to 250 degrees celsius), this air is used to heat the cabin and for anti-icing. Anti-icing uses air from the rear of the compressor and directs it through the compressor casing and the inlet guide vanes to prevent ice forming there. When anti-icing is used there will be a small rise in Turbine Outlet Temperature (TOT).

The Combustion Section

In this section the fuel is mixed with the air and ignited. The air ducts are shaped in such a way that the flame never comes into contact with the metal casing but instead is contained within a shroud of cooler air. A large proportion of the air is used for cooling. Once the fuel is lit and the engine is up to running speed, the combustion is self sustaining. The engine is turned initially by a starter. When there is enough airflow through the engine to keep everything cool, the fuel is ignited by the igniter plug. The fuel enters the combustion chamber through a fuel nozzle that atomizes the fuel. On ignition the gases expand and flow to the turbine section at an increased velocity. Approximately 60 to 80% of the air entering the combustion chamber is used to keep the liners cool. The fuel nozzle is highly polished and engineers have to handle it very carefully as the tiniest scratch will disturb the spray pattern and cause hot spots which will eventually damage the turbine blades. It has holes for delivering fuel.

Once the fuel is lit and the engine is up to running speed, the combustion is self sustaining. The engine is turned initially by a starter. When there is enough airflow through the engine to keep everything cool, the fuel is ignited by the igniter plug. The fuel enters the combustion chamber through a fuel nozzle that atomizes the fuel. On ignition the gases expand and flow to the turbine section at an increased velocity. Approximately 60 to 80% of the air entering the combustion chamber is used to keep the liners cool. The fuel nozzle is highly polished and engineers have to handle it very carefully as the tiniest scratch will disturb the spray pattern and cause hot spots which will eventually damage the turbine blades. It has holes for delivering fuel.

The Turbine Section

This section creates the power. The turbine inlet is the hottest part of the helicopter engine and it is too hot for temperature sensors to survive here. Temperature is therefore measured between the turbines by thermocouples (the readings are averaged and displayed in the cockpit instrument display) and is called the Turbine Outlet Temperature (TOT). The heat is kept to a manageable level by cold air extracted from the compressor which is driven through a connection by the turbine. The gases are directed through the compressor turbine blades (N1) thus ensuring that the compressor is continually powered. From there the gases pass through a two stage “Free Turbine” (N2). As the free turbine is not directly connected to the compressor, the engine is easier to turn during startup. The free turbine is connected to the Accessory gearbox which reduces the high speed of the turbine to a more manageable level. When more power is required, the compressor speed (N1) increases to supply more air. At the same time more fuel enters the combustion chamber and therefore N2 is maintained at a constant speed. The turbine blades are operating in a very hostile environment. As the temperatures are so high and the blades are spinning so very fast, centrifugal force causes the blades to stretch (blade creep). This is normal, however if the engine has had a hot start, the blade creep becomes much larger than normal and becomes permanent. The blades can make contact with the sides and expensive repairs will be required. Higher TOT temperatures are permitted during startup as the turbine is spinning relatively slowly. The N1 turbine is doing more work than the N2 turbine. It is also exposed to hotter gases. For these reasons the N1 turbine has only half of the service life of the N2 turbine.

The Accessory Gearbox

The accessory gearbox converts the high speed of the free turbine (N2) to a more manageable level. It has a drive-shaft powering the main rotor gearbox, a rear drive-shaft powering the tail rotor, a freewheel unit and attachment points for all the accessories such as fuel pump, tachometers, generator etc.

Compressor Stall

Compressor stall can occur on any turbine engine if the conditions present themselves. In order to meet the design requirements, the engine must have a relatively high power output, good fuel consumption and fast acceleration characteristics. For these reasons it is beneficial to operate as closely as possible to the stall angle of the compressor blades. Operating close to the stall angle has the following benefits:

- The volume of air passing through the engine is increased.

- The pressure ratio of the engine is increased thus increasing the power output.

- Turbine temperatures can be increased because of the greater airflow.

- The efficiency of the compressor and turbine sections are increased.

To reduce the risk of the compressor stalling during startup or acceleration, the fuel flow is carefully regulated. So what is compressor stall? Many pages could be devoted to explaining this but the following explanation should help answer the question. Compressor blades and vanes are aerofoils. The airflow over an aerofoil will separate and become turbulent if either of the following occurs:

- The velocity of the air passing over the aerofoil is too low.

- The angle of attack is too high.

If the airflow over an aerofoil separates then the aerofoil stalls. Approximately 80% of the air entering the engine is used for cooling. This means that much more air has to enter the engine than what is needed for cooling. The cooling air is used to control the length of the flame in the combustion chamber and prevent it from touching the sides of the container. The hot combustion gases are cooled by the cooling air and the cooling air is also heated by the combustion gases. This keeps the gases at an acceptable temperature as they mix and enter the turbine section. If too much fuel is supplied to the burner, there will be more than enough air to allow proper combustion. However as extra air is used during this combustion, there will be less air available for cooling and therefore the temperature inside the combustion chamber will rise. As the temperature rises, there will be more gases to be exhausted. It is possible that the volume of gases to be exhausted may exceed the capacity of the turbine and the turbine will “choke”. When this happens, the pressure inside the combustion chamber will rise rapidly and may equal or exceed the pressure that the compressor is producing. If the pressure in the combustion chamber is equal to the pressure of the compressor discharge air, then the compressor will stall. If the pressure in the combustion chamber exceeds the pressure of the compressor discharge air, then not only will the compressor stall but also the hot gases will flow from the combustion chamber into the compressor section. Both of these conditions will result in a loss of air into the combustion chamber. The flame will not have enough oxygen and will die, resulting in a rapid drop in temperature. As the temperature drops, the expansion is stopped (or greatly reduced). The turbine is no longer choked and the combustion chamber pressure drops to a very low value. The low pressure in the combustion chamber means that air can flow in the proper direction again. The compressor is no longer stalled and a “Surge” of air flows back into the combustion chamber. This extremely fast movement of air elongates the flame downstream and through the turbine causing another rapid expansion of the gases. The cycle repeats itself at approximately 120 times per second. Compressor stalls may or may not have an audible sound but there will often be a vibration. If the stall is severe a flame may emanate from the exhaust or a very loud backfire may be heard. Smoke may also be seen. If the proper corrective action is made immediately then it is unlikely that any damage will occur. The actions to be taken are:

- Reduce the throttle to flight idle.

- If the stall remains then close the throttle completely and shut down the engine.

Rapid throttle movements may induce stalling therefore it is a good idea to make smooth, slow throttle movements.

Summary

Helicopter engines have become very sophisticated. Turboshaft engines are extremely reliable as long as they are maintained and operated correctly. This post has only just touched on the subject of turboshafts but if you would like more information then please let me know.

Did you enjoy this post? Why not leave a comment below and continue the conversation, or subscribe to my feed and get articles like this delivered automatically to your feed reader.

thank you for a good message , i would like to keep intouch with you on that update and more differences and details about the turboshaft engneer

thank you